Welcome to Ollari e Conti

Benvenuti da Ollari e Conti – Bienvenue chez Ollari e Conti – Bienvenidos a Ollari e Conti – Willkommen bei Ollari e Conti – Witamy w Ollari e Conti – Добро пожаловать в Ollari e Conti

Casing Lines

Casing cleaning lines for the

extraction of mucosa

Other Equipment

Other equipment for further

processing

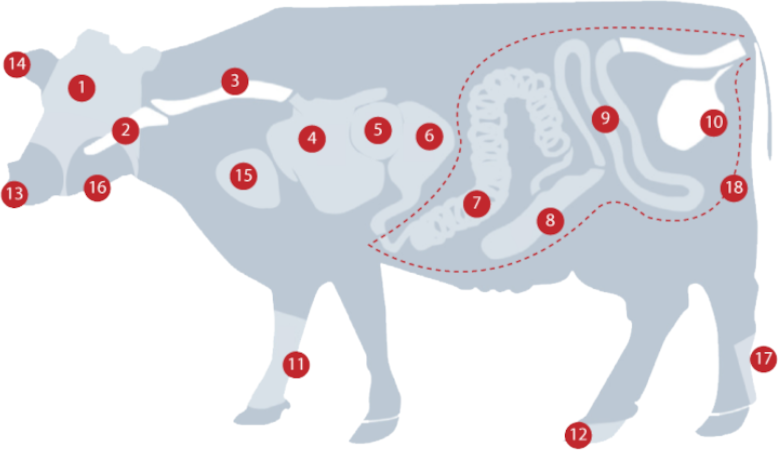

Species

Bovine

Click on the number to view

the appropriate equipment

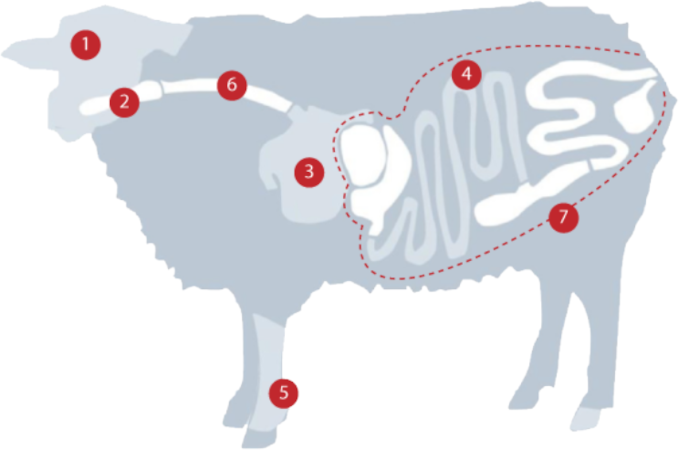

Ovine

Click on the number to view

the appropriate equipment

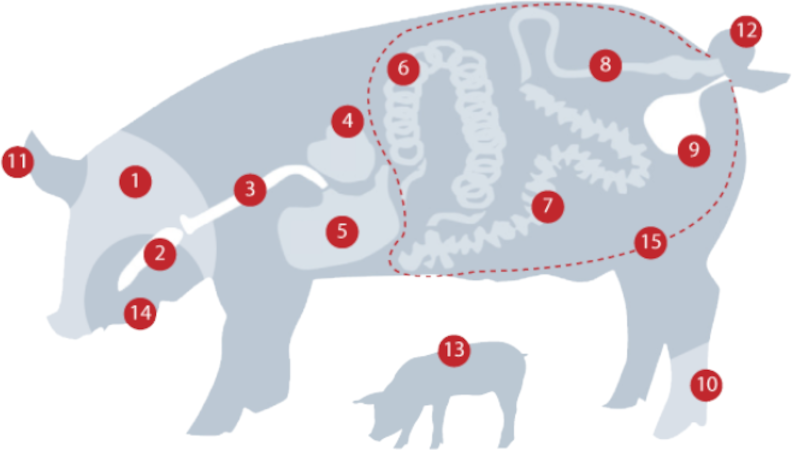

Porcine

Click on the number to view

the appropriate equipment